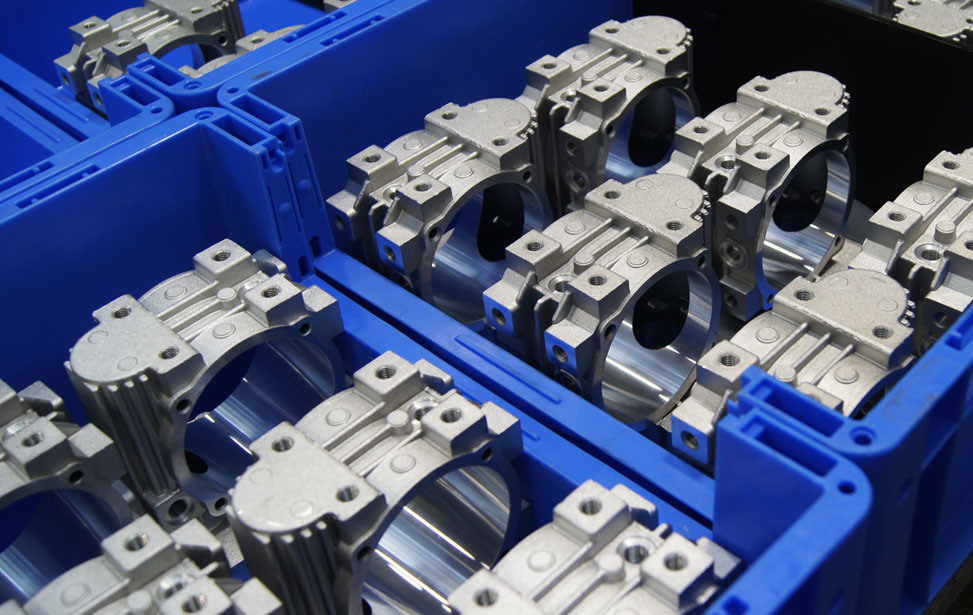

CNC machining is a sort of manufacturing process that controls the tools and machines used in industry. This process can be used to manufacture several machines such as mills, grinders, routers, etc., as it is compatible with a variety of materials such as wood, glass, etc. Skilled engineers are appointed in producing these machines that ensure the production of high-quality products with high accuracy. There are even shops that provide custom cnc machining service as per need.

What are these CNC machines?

Several CNC machines are provided by custom CNC machining service as owing the needs of the industry they are required in, and they are as follows:-

- CNC mills:- Rotary cutters are used with a milling machine to shape the products. These methods are popular because they can achieve the required shape according to the required depth.

- CNC lathes:- These are designed for objects of conical and spherical shapes. They are even capable of producing very complex tools with the help of a cutting tool placed at the center of the cutter. It helps in cutting out unnecessary material.

- CNC routers:- They can only be operated by skilled techs and are used to produce large dimension parts and cut large sheets of metal, wood, plastic, etc.

- CNC plasma cutters:- These cut materials using compressed air, gas, and electrical arcs. It is generally used to cut metal.

- CNC grinder:- with the help of a rotary wheel, these machines grind the materials repeatedly to get the desired product.

- CNC Electric discharge machines are used to give the objects inside the material the desired shape. Through repeated electrical release between two anodes, it is achieved. It is of two types, and they are wire EDM and sinker EDM. EDM is the short form for electric discharge machines.

Produce shapes with accuracy

As CNC machining can be used to produce various shapes with accuracy and are compatible with materials such as wood, plastic, glass, etc, it is highly preferred by industries such as the following:-

- food and beverage

- electrical and electronic

- automotive

- aerospace

- defense

- mining

- industrial machinery

- clothing

- telecommunication

- technology and security

The CNC uses software applications to ensure that the products that are produced are of high quality and accuracy. They are very helpful in optimizing designs, getting rid of any part of flaws, and also helps on reducing the cost of production.