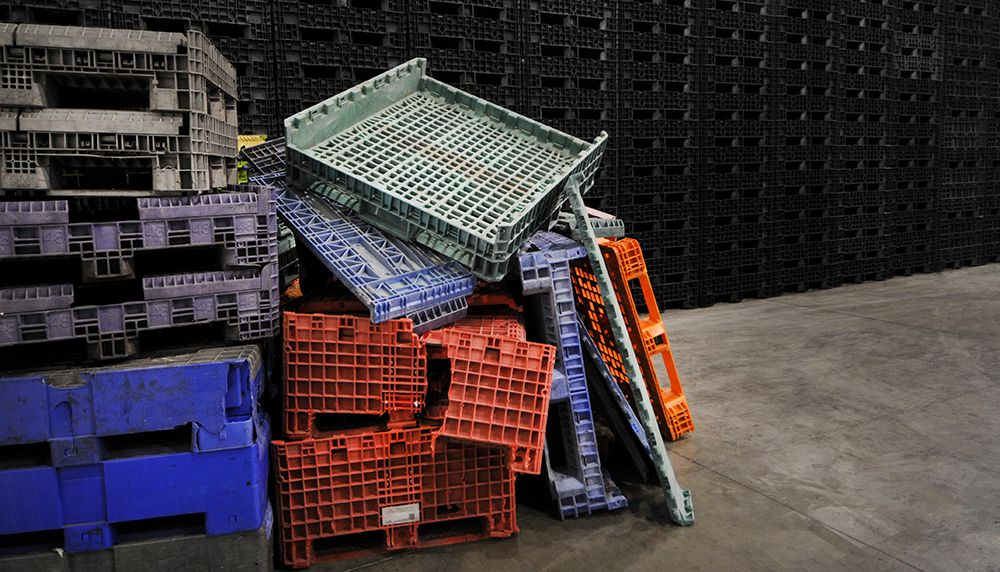

Bulk containers are essential assets in various industries, facilitating the storage and transportation of goods efficiently. Extending the lifespan of these containers is crucial for maximizing their value and minimizing operational costs. Here are some tips to help you prolong the lifespan of bulk containers:

- Proper Handling: Correct handling practices are essential for preserving the integrity of bulk containers. Avoid dropping or mishandling them, as this can cause structural damage, compromising their lifespan. Train personnel in safe handling procedures to minimize the risk of accidents and damage.

- Regular Inspection: Implement a routine inspection schedule to identify any signs of wear, tear, or damage early on. Check for cracks, dents, and other structural issues that may affect the container’s performance. Prompt repairs can prevent minor issues from escalating into major problems, prolonging the container’s lifespan.

- Cleaning and Maintenance: Keep bulk containers clean and well-maintained to prevent contamination and corrosion. Regularly clean both the interior and exterior of the containers to remove dirt, residue, and debris. Use appropriate cleaning agents and techniques recommended for the container material to avoid damage.

- Proper Storage: Store bulk containers in a designated area away from environmental hazards such as extreme temperatures, moisture, and sunlight. Exposure to harsh conditions can accelerate wear and deterioration. Utilize protective covers or shelters to shield the containers from the elements when not in use.

- Avoid Overloading: Adhere to the specified weight capacity of bulk containers and avoid overloading them beyond their limits. Excessive weight can strain the container’s structure, leading to premature failure. Use appropriate lifting equipment and distribute the load evenly to prevent stress concentration.

- Utilize Protective Packaging: When transporting goods in bulk containers, use appropriate packaging materials to cushion and protect the contents from damage. Padding, dunnage, and securing straps can help minimize shifting and impact during transit, reducing the risk of damage to both the container and its contents.

- Implement Proper Handling Equipment: Invest in suitable handling equipment such as forklifts, pallet jacks, or conveyor systems designed for use with bulk containers. Using the right equipment can minimize the risk of accidents and damage during loading, unloading, and transportation.

- Train Personnel: Provide comprehensive training to employees involved in handling bulk containers. Educate them about proper handling techniques, safety protocols, and maintenance procedures to ensure optimal performance and longevity of the containers.

- Repair and Retrofit: Address any structural or functional issues promptly by repairing or retrofitting bulk containers as needed. Reinforcing weak areas, replacing damaged components, or upgrading features can help extend the container’s lifespan and enhance its performance.